Wire Mesh Partitions - Type 120

Discover Our Flagship Line for Wire Partitions

Type 120 - Built for Life

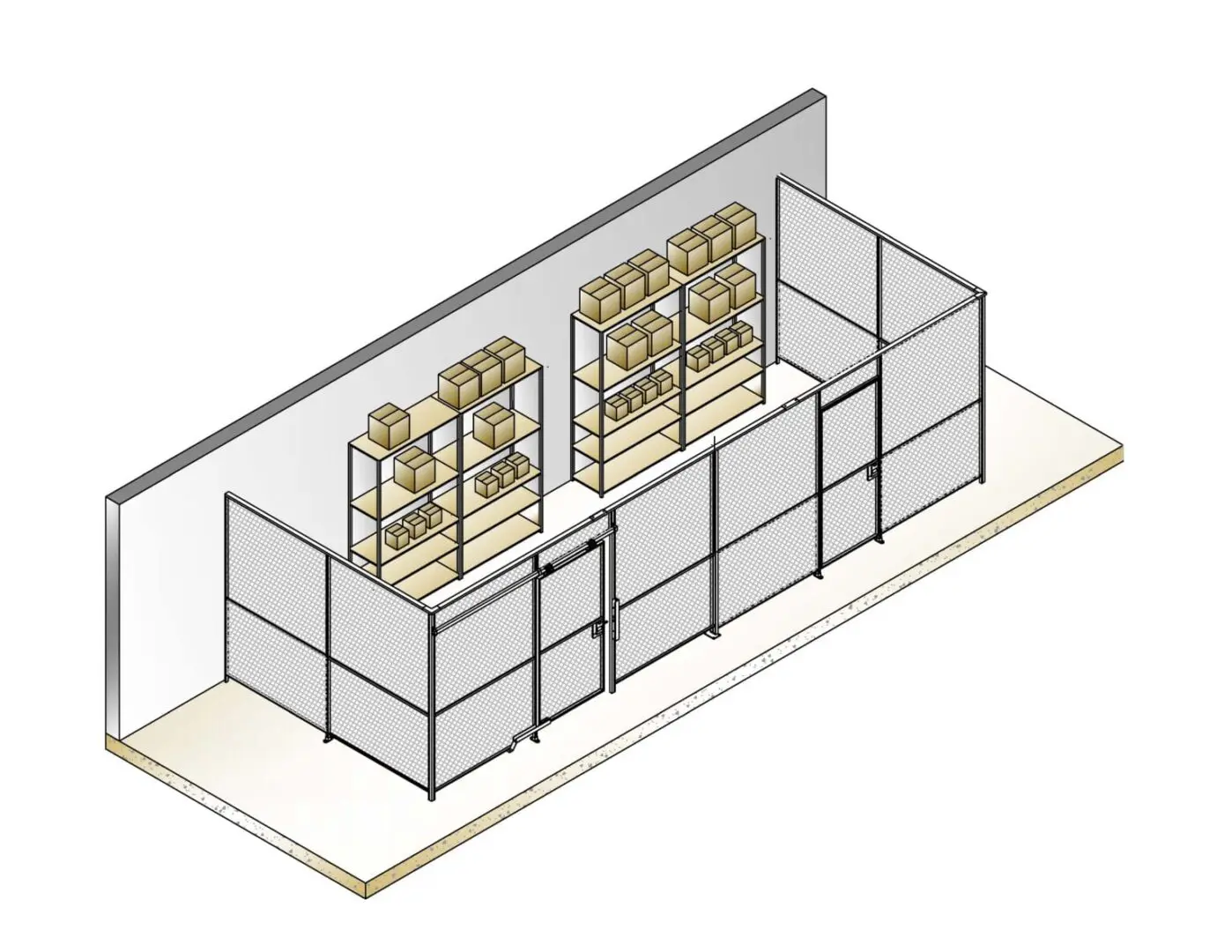

Our flagship line of wire partitions when a standard duty application is required. Type 120 is a durable wire mesh partition that can be utilized for security, protection, or separation projects. It is a modular system with endless standard and customization options to meet your specific needs. We encourage you to consult one of our sales professionals to discuss your specific preferences and design application.

- Modular design for standard and custom layouts, easy modifications, and future growth.

- Unobstructed view for enhanced visual accessibility, airflow, clear ventilation, light diffusion, sprinkler coverage, and security of contents.

- Wide range of door, gate, and lock options available.

- Three finishing options available: electrostatic painted enamel, hot dipped galvanized, and polyester powder coat.

Wire Mesh Partitions: A Durable, Modular, and Secure Design

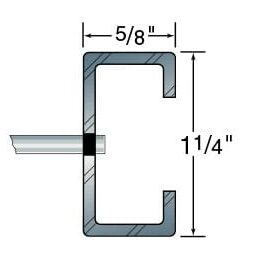

Newark Wire Works Type 120 wire mesh partitions are made of durable 10-gauge 1 1/2" x 1 1/2" diamond-woven wire mesh. The wire mesh is securely welded into a 1 1/4" x 5/8" Cee Channel frame.

Key Features:

- Modular

- On-site Flexibility

- Clear Ventilation

- Unobstructed View

- ADA Compliant

- Meets Fire Code Requirements

Door Options:

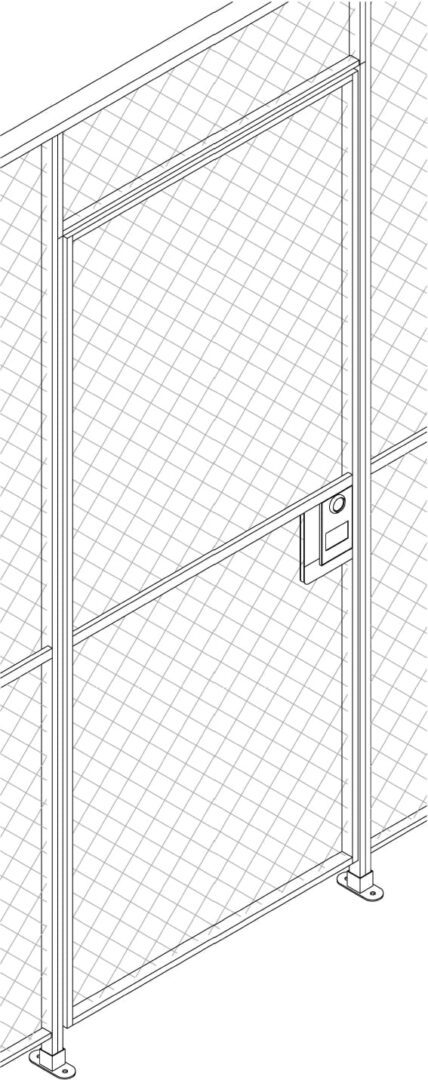

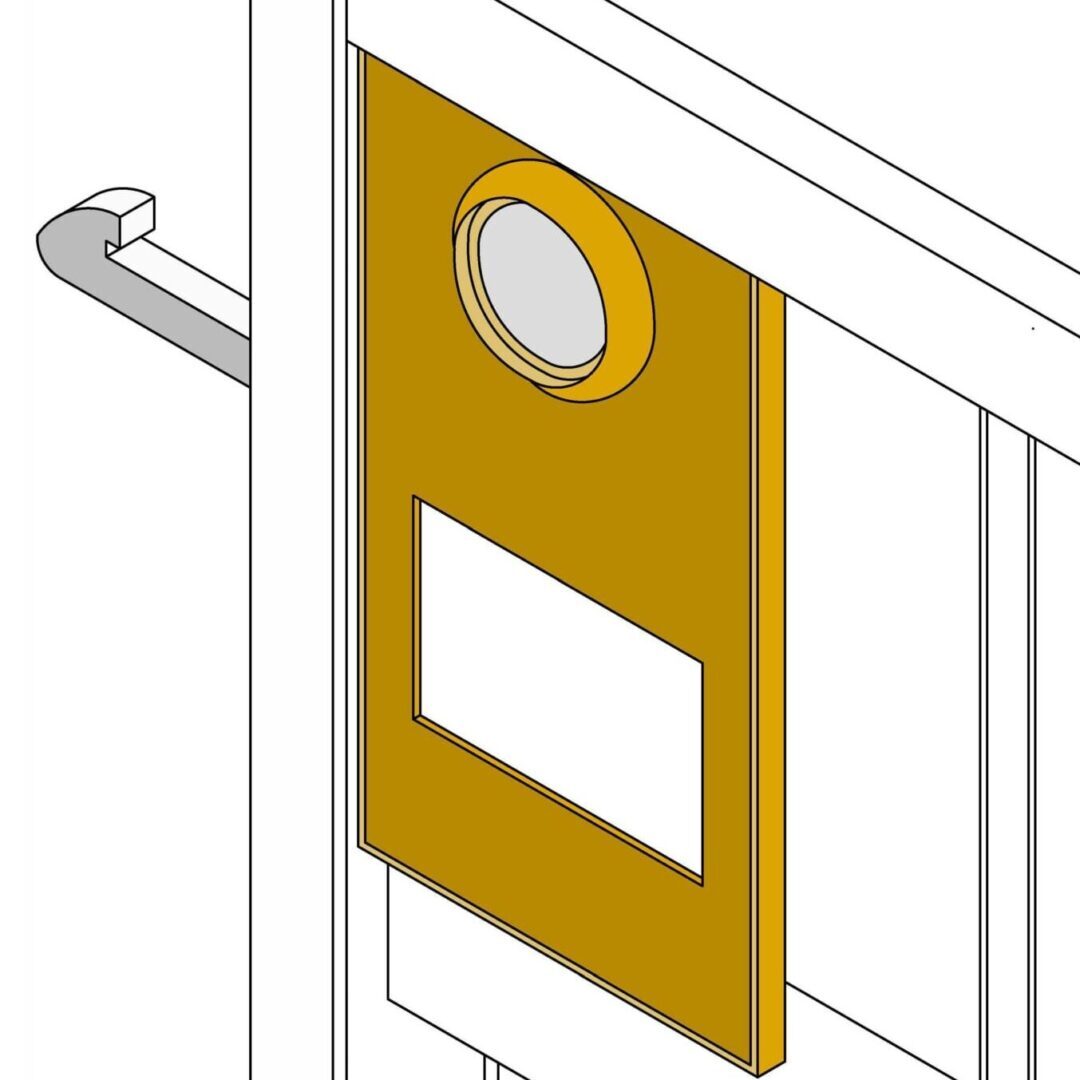

Hinged Doors: Typically configured in 3'-0", 4'-0", and 5'-0" widths and 3'-0", 4'-0", and 5'-0" depth. The standard height is 7'-0" high. Up to 10'-0" high clear door buck opening is available (ADA compliant).

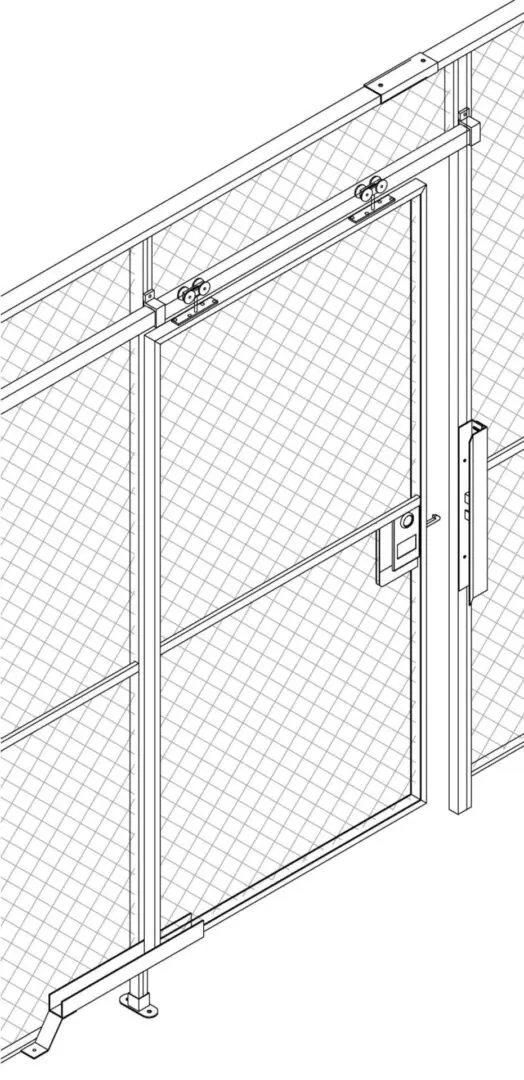

Sliding Gates: Configured in 3'-0", 4'-0", and 5'-0" standard widths and can go up to 10'-0" width openings. 7'-0" is the standard height, and heights can exceed 10'-0" high.

Wire Mesh Partitions - Type 120 Specifications

- 10 ga. (.135 ) plain steel, inter-crimped and woven into a 1 1/2" diamond mesh. Mesh is then passed through and securely clinched or welded to the channel frame.

- Vertical Frame: 1 1/4" x 5/8" x 13 ga. steel "C" channel; Horizontal frame: 1" x 1/2" x 11 ga. steel channel

- Mid-Rail: 1" x 1/2" x 11 ga. steel channel; Hinged Doors: Vertical frame: 1 1/4" x 5/8" x 13 ga. steel "C" channel

- Horizontal Frame: 1" x 1/2" x 11 ga. steel channel; Mid-rail: 1" x 1/2" x 11 ga. steel channel; Capping: 1/8" x 1 1/4" steel flat bar

- Lock: Marks 3700 series

- Vertical Frame: 1 1/4" x 5/8" x 13 ga. steel "C" channel; Horizontal frame: 1" x 1/2" x 11 ga. steel channel

- Mid-Rail: 1" x 1/2" x 11 ga. steel channel; Capping: 1 1/2" x 3/4" x 11 ga. steel channel

- Lock: Marks 3700 series

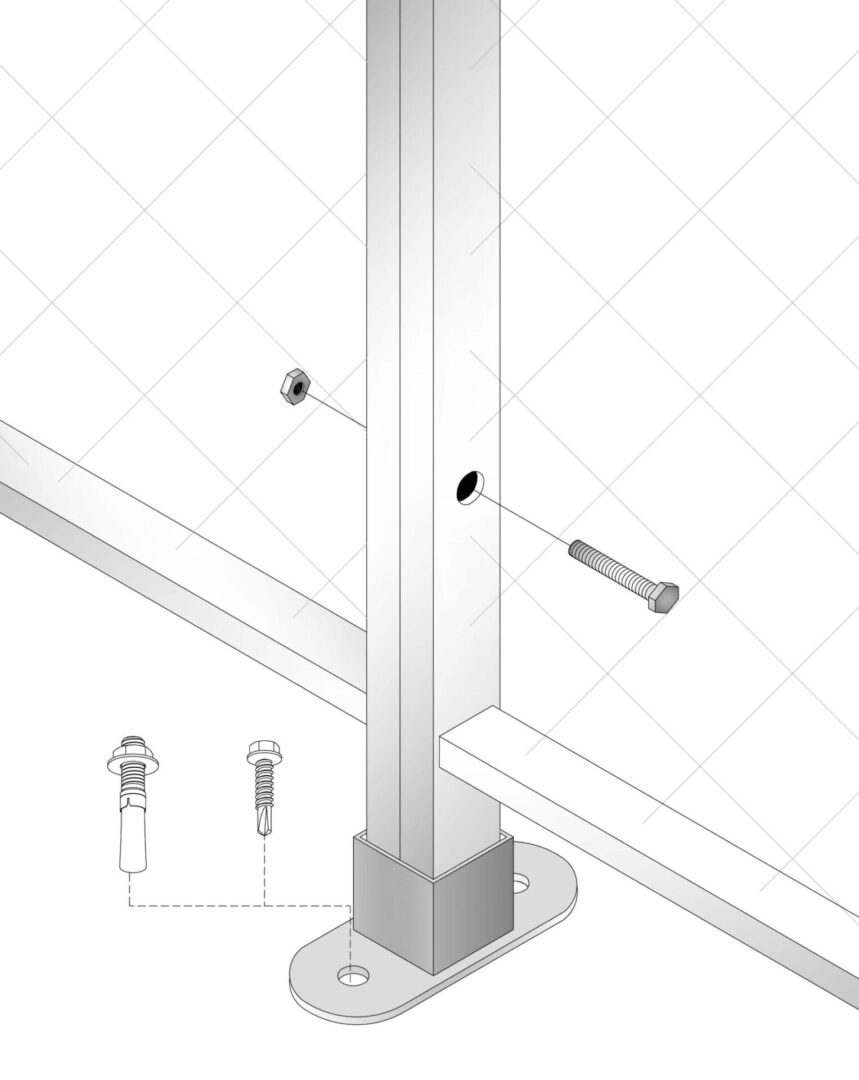

- Tube: 2" x 2" x 14 ga. steel tube - Heights: 7'-0" - 18'- 0"

- Tube: 2" x 3" x 14 ga. steel tube - Heights: 18'- 1" - 24'- 0"

- Tube: 2" x 4" x 14 ga. steel tube - Heights: 24'-1"- 30'-0"

- Tube: 2" x 6" x 14 ga. steel tube - Heights: 30'-1"- 40'-0"

- Type: For 8'-0" high partitions and below long spans (15'- 3" o.c.); attaching to access flooring or concrete

- Type: 3"x1 1/2" x 11 ga. Steel channel with bolt holes to match panel-welded base plate with 4 holes for tek screws into the access floor into the concrete floor below the access flooring: 3"x3"x11 ga. Steel square tube with 8"x8"x1/4" welded base plate with 4 holes with 3/8" diameter wedge anchors into the concrete floor.

Ceiling Options

Ceiling panels are available if you need an extra layer of security. We recommend you have at least 3-5 inches of spacing between the room ceiling and the top of the wire mesh locker.

Adding a wire mesh ceiling not only provides an extra layer of security but also allows light, ventilation, and sprinklers’ heads to pass through the locker.

Additional Options

Other accessories may be required to complete our project. See below and choose the right options for your next project:

Special Door Hardware Options

- Magnetic Lock

- Electric Strike

- Combination Lock

- 1600 Series Door Closer

- Heavy-Duty Door Closer

- Lever Lock

- Wing Pull

- Panic Bar Electric Strike

- Mage Gallery

Finishes - 3 Styles To Fit Every Application

Electro-static Paint Enamel

Standard Paint Colors:

Shop-applied alkyd-based air-dried enamel paint that is electrostatically applied. This is our basic entry-level finish, which can be easily touched up in the field as needed.

Battleship Gray

Black

Safety Yellow

Safety Orange

Safety Blue

Polyester Powder Coat Option:

Five-stage polyester powder coat is one of the best finishes on the market, with increased finish strength than the standard paint finish.

Hot Dip Galvanizing Option:

Five-stage polyester powder coat is one of the best finishes on the market, with increased finish strength than the standard paint finish.

Standard Construction

Framing

Angle Iron Frame

Thickness: 1/8"

Size: 1 1/4" x 1 1/4"

Steel Type: Carbon

Typical Lockset

Mortise Lockset:

Marks 3700 series

Standard for Both Hinged Doors and Sliding Gates

Wire Mesh

Gauge: 10 GA (.135)

Mesh Opening: 2" x 2"

Mesh Type: Square Welded Wire Mesh

Finish

Standard Colors:

Battleship Gray

Gloss Black

(Other colors Available)

Applications:

- Server Cage / Colocation Cages

- Tool Cribs

- Warehouse Storage

- Inventory Management

- Pharmaceutical Drug Storage

- DEA Compliant Cages

- Firearm Security

Product Gallery

Typical Panel Connection

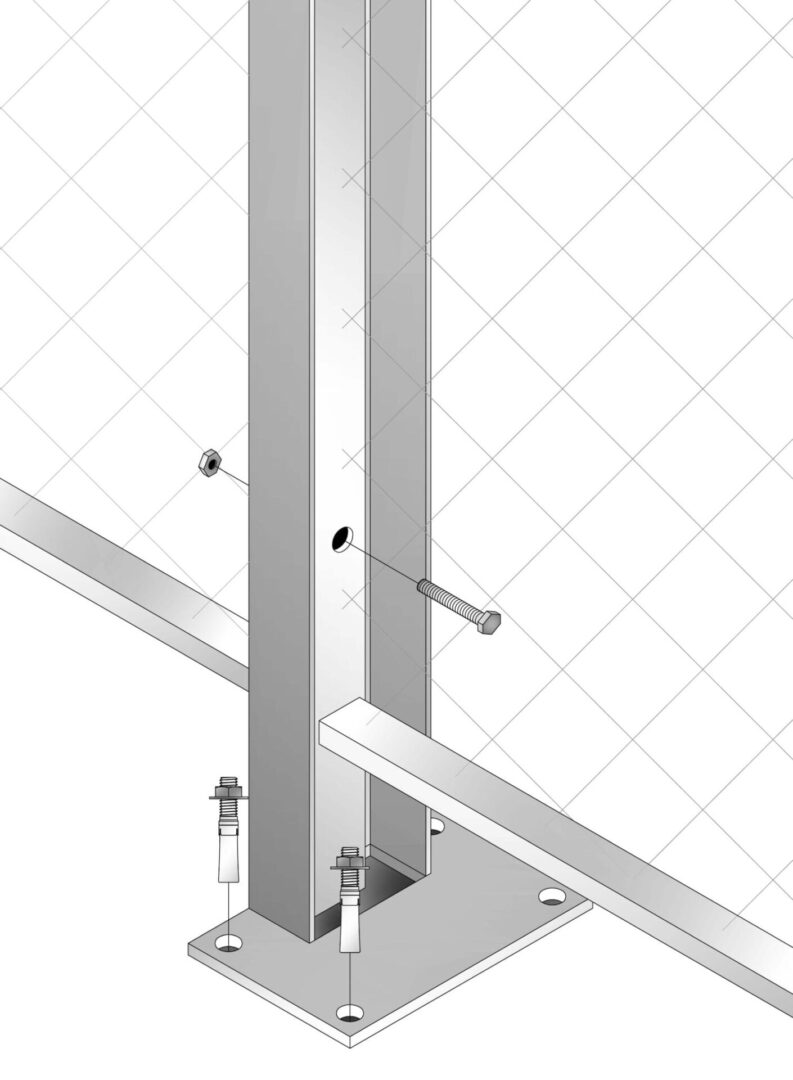

Typical Line Post Connection

Note: Line Posts are to be placed in between panels every 10-15 feet to meet rigidity standards.

Questions? Let one of our experienced Sales Representatives help you every step of the way. Call (732) 661-2001.